Product details:

After extensive CAD development based on the 3D scan of the OEM engine cradle, tested with the CAD FEA (Finite Element Method) method and on the road, you can now purchase a cradle for the front of your vehicle. List of cars below.

We use the same T45 tubes as in the WRC cars, our wishbones provide increased stiffness and extra fit. All factory parts are bolted to this unit, no further modification is required.

"T45" tube is a very unique seamless carbon steel tube that has been used in many applications in different industries. It is more resistant than the Co-Mo 4130 tube also used in motorsport.

It is widely used in the aerospace industry and in equipment such as pilot seats and crew seats due to the ability of the materials to withstand high G-forces without cracking or splitting.

This material is carbon and manganese based and meets aerospace specifications set by UK standards.

Properties

Traction: 700 - 900MPa,

0.2% Efficiency 620MPa minimum

Hardness test: 201min - 262 max HB or 210min - 275max HV

Advantages :

- - Can be used with our lowered and adjustable tubular front wishbones

- - Weight of the cradle 13kg, this is a weight saving of 6.5kg compared to the OEM cradle which weighs 20kg

- - One and only mounting position

- - Increased chassis rigidity to improve driving performance

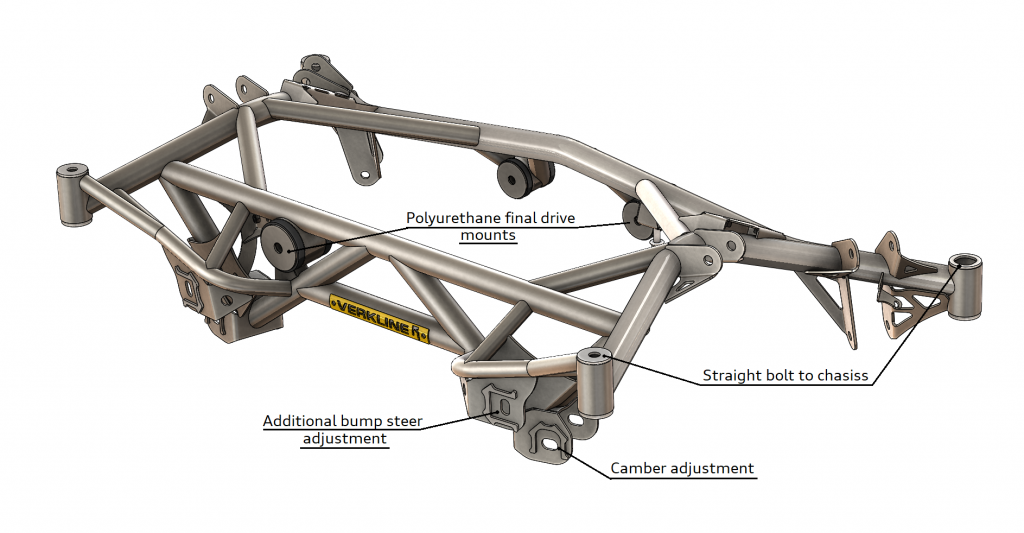

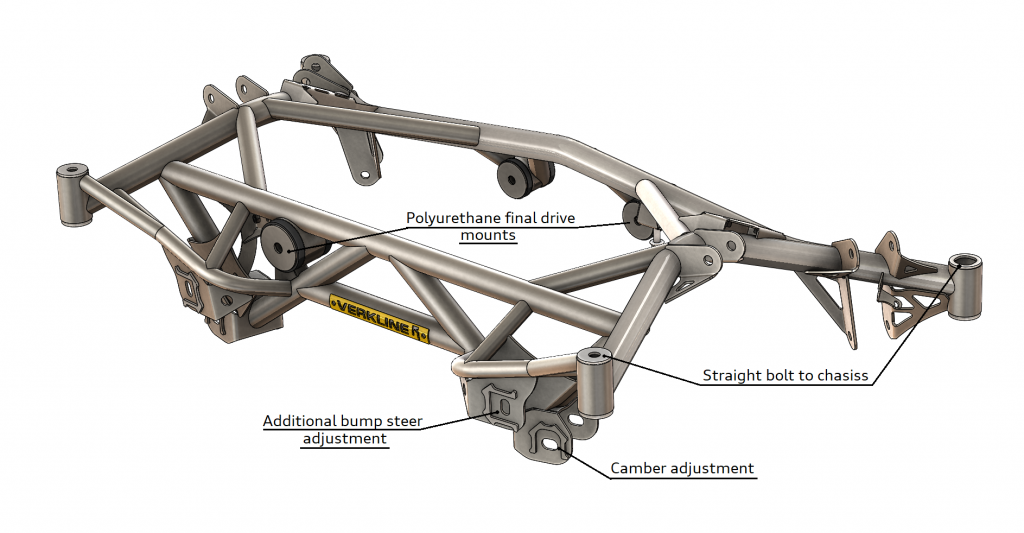

- The rear final drive has moved 10mm up (about ⅜ ") to reduce the loads on the CV joints. We are changing its position, because if you lower the car the shafts are often in the wrong position. is made to prevent premature wear of constant velocity joints.

- Removed rubber mounts from a rear subframe on the body and created a single mounting position.

- We changed our cradle to bolt directly to the frame through smaller mounting holes. This is done to prevent the displacement of a rear subframe under heavy overloads.

- Additional steering adjustment by shock on the cradle. You can now change the amount of direction per bump moving up and down from the pickup point of a rear pinch link.

- Replacement of the rear final drive rubber mounts with black racing car polyurethane. Under torque, the trans moves on the factory mounts. Our 85ShA polyurethane mounts dramatically reduce this movement, greatly aiding the transfer of torque from the drivetrain to the shafts and wheels by removing slope in the drivetrain.

Characteristics :

- - Better accessibility under the car allowing the triangle change without any other disassembly constraint

- - T45 tubes (BS4 T45 to BS5T100 / BS6S100) imported from UK and S355 metal sheets

- - All TIG welded components

- - Supplied painted (epoxy powder coating) black

- - two front anti-roll bar attachment points. An additional 20mm at the front are the second attachment points which free up space for the dry oil sump piping

- - additional space for easy removal of the extended oil sumps,

- - works with the Magnus dry sump kit,

- - Can be used with OEM or aftermarket wishbones

What's included:

- - Lightweight reinforced painted cradle with VERKLINE polyurethane support

- - Set of steel locking triangle positioning shims (24 pcs.) For positioning the arm links (allows the direction to be adjusted by bump) (-5 / -4 / -3 / -2 / -1 / 0 / + 1 / + 2 / + 3 / + 4 / + 5mm).

- - kit of bolts and nuts to mount the toe links (zinc plated, grade 10.9),

- - set of steel locking triangles positioning shims (8 pcs.) for positioning camber triangles (-3.5 / 0 / +3.5 mm),

- - polyurethane racing mounts for the rear differential,

- - exhaust system mounting bolt (Zinc plated, grade 10.9).

- - Printed installation instructions

Compatible with :

- - Toyota Supra A90

- - Toyota Supra A91

- - BMW Z4 G29

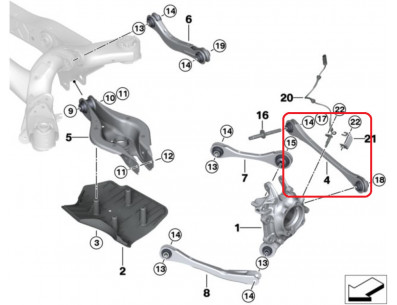

This Kit Replaces:

- - 33316794865

- - 33316795830

- - 51206WAA04

- - 51206WAA05

Note: It is necessary to use a pair of adjustable tie rods in order to set the correct amount of toe-in as there is no adjustment on the subframe (replaced by shock steering adjustment). If you don't already have it, you can find it here -> LINK.

Note: Sold for off-road, race track and racing applications only. Installing this type of part will cause noise and other vibrations in your vehicle. We strongly advise you to assemble the cradle in a qualified and experienced workshop who will know what to do.

This piece is custom-made to order so when you order this product and we are launching production there will NEVER be taken exchanged refunded, thank you to take NOTE

STR Performance is official distributor of VERKLINE products, if you are looking for a part from VERKLINE that we do not have on our site, do not hesitate to contact us via our Contact page, so that we can give you a price and a deadline .